Testing of AEL Electrolyzers

The generation of green hydrogen through electrolysis plays an enormous role in the worldwide growth of hydrogen production. The focus is on three different processes: PEM electrolysis, SOEC electrolysis and AEL electrolysis.

Alkaline electrolysis - AEL for short - is the longest established type of electrolysis. The market maturity of the technology is a decisive factor on the way to making green hydrogen marketable and thus replacing fossil fuels. In order to further advance electrolysis capacities, reliable test and inspection solutions are needed at cell, stack and system level. With over 20 years of expertise in this segment, HORIBA FuelCon is your trusted partner.

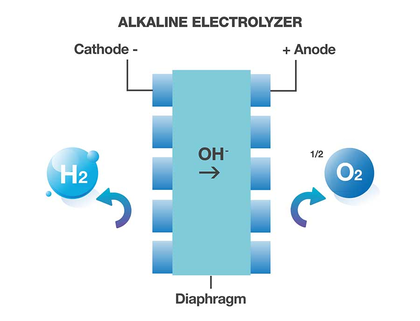

Working Principle of a Alkaline Electrolyzer

The alkaline electrolyzer splits water into two components – hydrogen and oxygen. The electrolyte is potash lye, which has a concentration of 20 to40%. Pure water is fed into the cathode of the electrolyzer where it is split by means of a catalyst. Hydrogen is produced directly on the cathode side, whereas the oxygen ions are passed through the alkaline solution and react to form oxygen on the anode side.

State-of-the-art water electrolyzers with alkaline elektrolytes currently boast competitive and better efficiencies than acid PEM water electrolysis due to the material used.

Advantages of a AEL Electrolyzer

- Advanced technology level

- High long-term stability due to exchangeable electrolyte and lower dissolution of the anodic catalyst

- Low investment costs due to low-cost catalysts

- High gas purity due to lower gas diffusivity in the alkaline electrolyte

- An alkaline electrolyzer is particularly recommended for very large systems

How we can support you

HORIBA FuelCon supports you with years of expertise in reliable testing and inspection capabilities. Our activities are based on five core values: quality, flexibility, reliability, safety and automation. Our solutions are contributing to the energy transition and enable you to significantly increase your production capacities.

For PEM and AEL electrolyzers, our product range includes the Evaluator EC and Evaluator ES series, which are ready for immediate use in high-pressure applications. Technically, PEM and AEL electrolysis are so similar that both technologies are implemented in the HORIBA FuelCon test stations. We enable automated testing in the range up to 5 MW at the highest currents and low voltages at the same time. As a basis, we offer you durable components in combination with reliable safety features.

HORIBA FuelCon is constantly optimising our product solutions. Based on years of experience with our test and manufacturing systems for fuel cells and batteries, we can make great strides toward improving your electrolyzers. We are happy to integrate your individual test requirements into our work. Do you have specific requirements for your AEL electrolyzers? Contact us and talk to our project engineers.

Our Advantages at a Glance

- Robust components, highest control accuracies as well as specially developed control algorithms enable the testing of AEL electrolyzers

- Flexible solutions regarding the specific configuration of the media supply, controllable electronic loads and independent feedback loops

- Real-time monitoring of all relevant system parameters and comprehensive safety assessment for worry-free operation

- Fully automated unattended testing using the HORIBA TestWork automation system developed in-house

- Individual test solutions on request of our customers

Things to know:

We develop customized test systems directly tailored to your needs. Learn more about our offers.

You can find additional comprehensive information in our technical product brochure. Additionally, we are available to discuss your requirements over the phone.