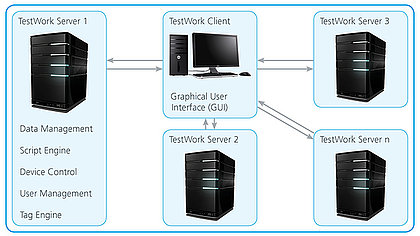

HORIBA TestWork Client-Server-Structure

A test station consists of process engineering components and electrotechnical components, a HORIBA TestWork process server, a HORIBA TestWork database server (optional) and a HORIBA TestWork Client. The HORIBA TestWork process server is a specific computer hardware that provides different hardware classes depending on the requirement. It also hosts the HORIBA TestWork Server.

In terms of the HORIBA TestWork automation concept, HORIBA FuelCon relies on a modern client-server architecture. Diverse advantages for test station operation arise thereof that for example increase operational reliability or make the administration of entire test fields a child’s play. Depending on the test station type, client and server are locally installed on the same hardware or run on separate systems communicating with each other via Ethernet.

Different applications require different clients. There are HORIBA TestWork Clients for research and development of programming, visualization, data analysis and tests. For the use in production, the HORIBA TestWork Client Operator Panel is used in order to operate end-of-line test stations or formation test stations. A client can also be used to control an existing test field by means of a proprietary software provided by the customer.

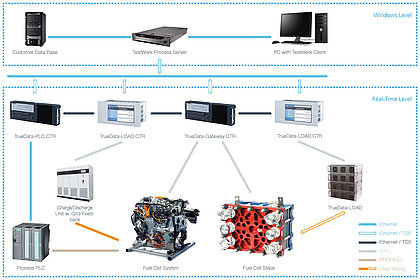

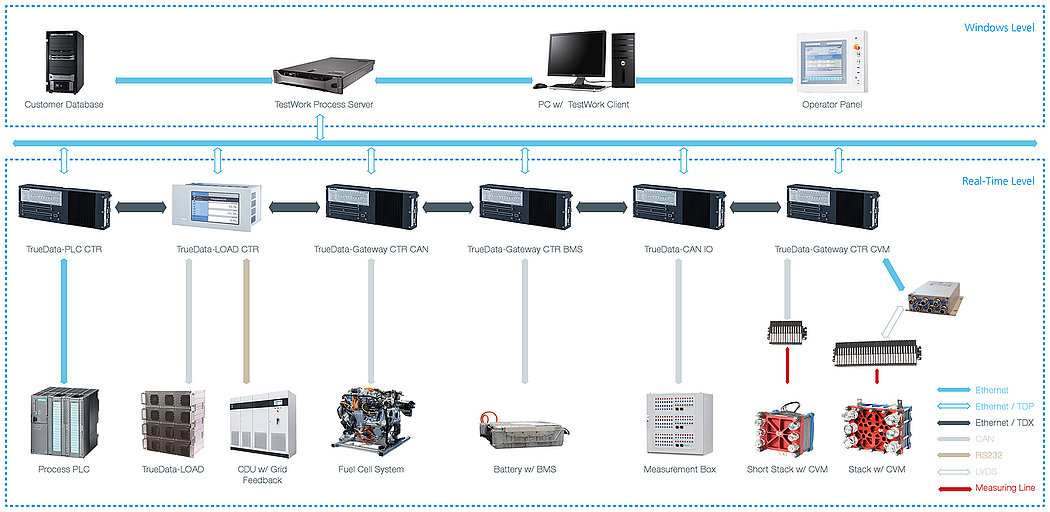

In addition to the client-server architecture, the HORIBA TestWork automation concept is also divided into Windows level and real-time level. The Windows level comprises all components of client-server architecture and is operated by the test station operator through HORIBA TestWork automation software. With end-of-line test systems, the Windows level is also referred to as operator level.

The real-time level comprises relevant test station components and is especially characterized by the TrueData Controllers. These controllers log data with up to 1 ms in “real time” and can execute test runs independent from the Windows level via sequence or acquire data, respectively. Windows level and real-time level are connected to each other via Ethernet.

Windows Level

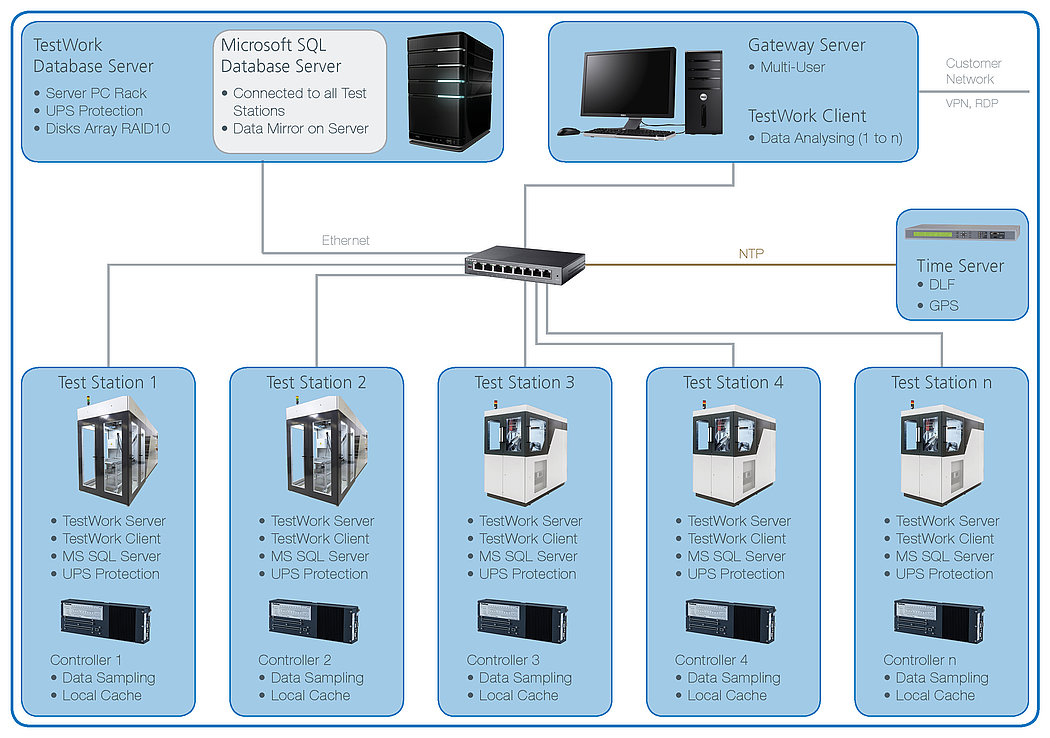

The hardware of the Windows level or operator level comprises the process server (HORIBA TestWork Server with tag engine, script engine and database manager) and the client computer. For this purpose, HORIBA FuelCon uses default hardware components of established manufacturers including worldwide warranty and maintenance options.

For test station operation, our automation software HORIBA TestWork also runs on the Windows level. In the course of this, test runs can be executed in a manual, partly automated as well as in a fully automated way. If test sequences are to be realized independent from the Windows level in real time, corresponding sequences are to be created and to be loaded to the controller.

The communication within the Windows level takes place via Ethernet with the individual components running on Windows systems. The HORIBA TestWork process server forms the interface between Windows level and real-time level, which is why especially high-performance and reliable hardware is used here.

In order to still ensure a maximum of data security especially in larger test fields, HORIBA FuelCon offers a number of additional options:

- Database server

- Gateway server for secure communication in the customer network

- Climate-controlled server cabinets

- Power failure management (IPS)

- Time server

Real-Time Level

The real-time level ensures sampling sensor values and actuator values with consistent intervals in the range of several minutes up to a minimum of 1 ms. All devices of this level work independently from the Windows level.

Real-time level devices are:

- TrueData-LOAD Controller

- TrueData-PLC Controller (controller for real-time communication with the PLC)

- Electrochemical Impedance Spectroscopy

- TrueData-Gateway Controller CAN (gateway for CAN)

- TrueData-Gateway Controller BMS (gateway for battery management systems)

- TrueData-Gateway Controller CVM (gateway for cell voltage measurement)

All measurands and process parameters (tags) of this level receive a timestamp with an accuracy of 1 ms. The data exchange with the Windows level is carried out through a default Ethernet interface. TrueData real-time controllers additionally dispose of local data logging capacities in order to compensate malfunctions of the Ethernet network. For short reaction requirements in the milliseconds range, TrueData Controllers can communicate with each other through a real-time protocol (TDX).