Quality Assurance in the Production Process

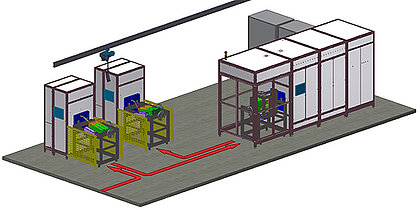

The series production of fuel cells or entire stacks is a highly complex process in which many work steps are interlinked. To ensure the desired product quality at the end of the production process, HORIBA FuelCon offers the Evaluator End-of-Line (EOL), a test system that can test fuel cells and stacks in a range of up to 250+ kW. It can be used to carry out fast-cycle automated quality tests for cells, MEAs and stacks.

The system is always designed according to customer specifications, whereby our cost-efficient design allows solutions to be realised for all requirements. These range from simple test stations with manual contacting or execution to automated systems that enable automatic contacting of the test object by means of a conveyor belt. To optimise the test time, important steps such as filling and emptying coolant and leakage tests can be carried out automatically.