Testing of SOEC/rSOC Electrolyzer

Electrolysis is currently the most promising process for generating green hydrogen. Alongside the intensively researched PEM electrolysis and AEL electrolysis, which has been established for decades, SOEC electrolysis is the newcomer of the technologies.

SOEC electrolyzers have the potential to make an important contribution to the transition to a hydrogen economy. Due to the use of steam under high operating temperatures, the technology is particularly efficient. SOEC - Solid oxide electrolyzer cell - colloquially known as high temperature electrolysis, is currently in the important phase of pilot plant testing, therefore reliable test stands for SOEC electrolyzers are needed. HORIBA FuelCon offers solutions for single components as well as for stacks and complex energy systems.

Working Principle of a SOEC Electrolyzer

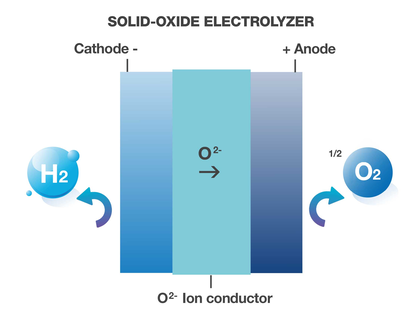

The general function of the SOEC electrolyzer is to split water vapor into pure hydrogen and oxygen. The process takes place at temperatures between 600°C and 1050°C to achieve high ionic conductivity of the mostly ceramic electrolyte. Water vapor is fed into the cathode of the electrolyzer. When a voltage is applied, the reaction starts and the vapor moves to the cathode-electrolyte interface where it is reduced. This forms pure hydrogen and oxygen ions, which pass through the electrolyte and are oxidized to oxygen on the anode side. The ceramic electrolyte thus serves not only as an ion conductor, but also as a spatial separation of the two half cells.

The structure of a high-temperature electrolytic cell is similar to that of a solid oxide fuel cell (SOFC), but in electrolysis the fuel electrode serves as the cathode and the oxygen electrode as the anode. The technology is suitable for a bi-functional design - a reversible solid oxide fuel cell (also referred to as SOFC-SOEC combination).

Advantages of a SOEC Electrolyzer

- High efficiency with a degree of efficiency up to 84 %

- Low demand for electrical energy

- Very high purity of hydrogen (99.9 - 99.9999 %)

- Great potential for connection to industrial processes that provide large amounts of waste heat

- Can be used in co-electrolysis operation for the production of green synthesis gas

How we can support you

HORIBA FuelCon offers reliable test stations for SOEC single cells, short stacks, stacks and systems. With our expertise, we support you in the development of your test item from the requirement profile through quality assurance to the safety concept. Our automated solutions enable performance and long-term testing to set the technical course for safe and reliable SOEC electrolysis operation.

Our systems include all necessary features for SOEC testing, including cathode humidification, flow and temperature control, inert gas purging and electronic load management. The Centerpiece is HORIBA FuelCon's proprietary pulsation free evaporator assembly. Due to the constantly uniform evaporation of the water pressure, fluctuations and associated fluctuations in the cell voltages are avoided. The steam production can be carried out with or without the use of carrier gas.

We enable tests in the power range up to 100 kW. We are interested in your personal requirements and present our solutions to you. Our goal is to support you in the further development of your SOEC electrolyzers.

HORIBA FuelCon is networked worldwide and sets standards in terms of flexibility and process flow. For fully automated testing of SOEC electrolyzers we offer our SOFC test stations of the Evaluator HT series. For all information about our products please refer to our product data sheets.

Our Benefits at a Glance

- Flexible solutions for all types of applications with electrical power requirements up to 100 kW

- High efficiency at operating temperatures up to 1050 °C

- Stable pressure management due to low-pulsation evaporator assembly

- Reversible e-load with smooth changeover between fuel cell and electrolyzer operation

- Logistical process optimization to reduce cycle times

- Fully automated concept for safe, reliable, unattended operation through our advanced HORIBA TestWork automation

- Further requirements on request

Things to know:

We offer a selection of standard test systems specifically designed for your hydrogen testing needs. Here you will find an overview of all information.

Our technical product brochure contains further detailed information. Alternatively, feel free to give us a call to discuss your requirements.