Quality Assurance within the Production

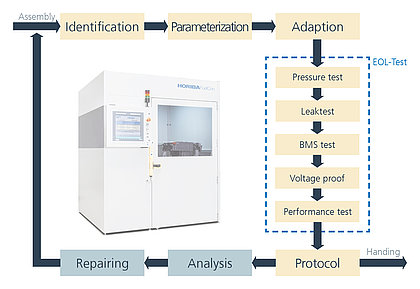

The End-of-line test station is located at the end of the battery assembly and it permits checking of quality-relevant parameters. The scope of testing includes pressure and leak tests, insulation test and voltage proof, various performance tests as well as testing and integration of the battery management system (BMS), including the final classification or good/bad decision.

With the product range Evaluator EOL, HORIBA FuelCon offers different testing systems for quality assurance within the battery production. These systems are used for example as cell testers for inspection of delivered cells immediately prior to the cell assembly into the battery housing. Likewise, the complete functional test of the battery, including a test of typical performance parameters at the end of the production process is possible.

For the testing requirements in battery production HORIBA FuelCon offers customer-specific solutions for the following applications:

End-of-Line Testing

After the battery and pack assembly, the quality and parameter control of the produced units is necessary. Therefore, HORIBA FuelCon offers semi or fully automated end-of-line battery testing systems.

These test cells are usually designed and realized customized and contain the following basic features:

- User-friendly operator interface through touch panel

- Fully automated performance with “One-button-operation”

- DMC scan including connection to assembling data bases

- Manual or fully automated adaptation

- Functional testing

- Performance testing

- Electrical testing including isolation tests

- Testing and calibration of BMS

- Integration into assembly automation

Incoming Goods Inspection

In particular before the battery or pack assembly, a quality and parameter check of the delivered cells is indispensable. In addition to the actual incoming goods inspection, the determined cell parameters are used to select optimal grouping variations in the compilation of cells to complete packs. The basic procedure for an incoming goods inspection is shown in the structure chart.

Cells testers are custom designed and realized and have the following basic equipment:

- Integration into manufacturing automation

- Fully automatic processes

- Identification with DMC scan

- Parameterization through connection to an assembling database

- Manual or fully automatic adaptation

- Function test or performance test

- Cell voltage measurement

- Temperature monitoring

- Test for good/bad decision

Depending on the safety specification, the test can be performed in open or closed test cabins.

Integration of additional Components for Product Validation

Within several design processes, for design modifications or within mass production, mechanical tests (vibration), climatic tests (thermal or environmental chambers) or electrical tests (charge /discharge units) are required. With HORIBA FuelCon test stations an overlapping of these different testing procedures can be realized.

During a validation, the specific test operation, furthermore, requires the communication with different Battery Management Systems (BMS), including rest bus simulation. The rest bus simulation is operated completely by the test station.

The focus is to provide systems with high reliability, easy operation for trained staff as well as high operation safety that meets the respective requirements.

HORIBA FuelCon offers a broad range of solutions, tailored to the respectively application conditions:

- Charge / discharge units with climatic chamber

- Charge / discharge units with shaker

- Coupling of climatic chambers and shaker

- Parameter adjustment with control devices

- Communication with battery management systems (BMS)

- Residual bus simulation

For further detailed information please read our technical data sheet for EOL that are available at our download area. Or just give us a call! We will be happy to discuss your requirements.